Efficient manufacturing requires appropriate means of production – not always automation. In particular, with small production runs, manual presses are often the most cost effective solutions.

We are continuously developing the range of manual presses so that you can achieve your production goals. The expertise we have gained from our exposure to numerous production applications has been implemented in our new models. Therefore, we can offer a wide range of manual presses to suit all requirements.

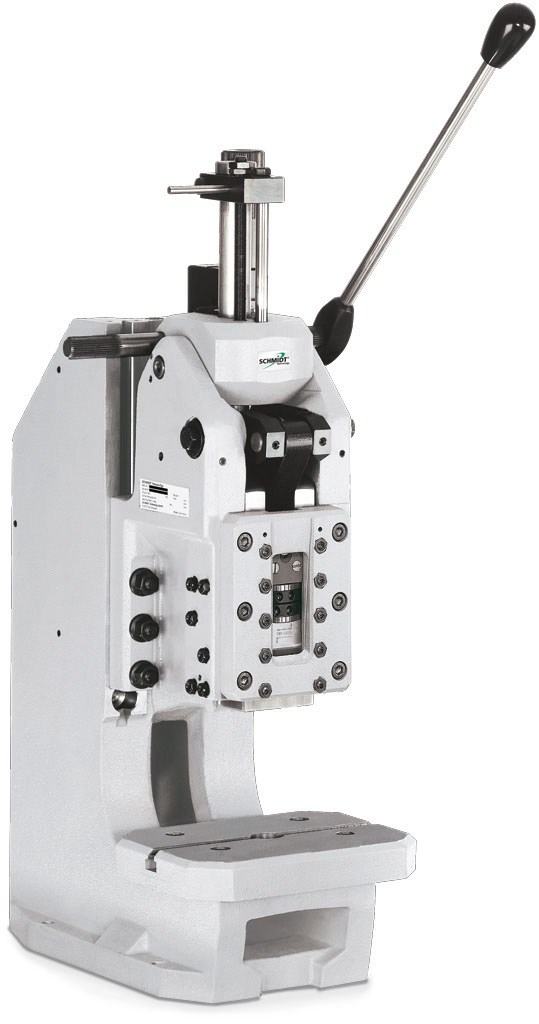

Depending on the application, there is a wide selection of rack and pinion presses and toggle presses to choose from. Furthermore, a modular product design gives you the opportunity to choose the appropriate press for your application.

Features

- Flexibility

- Long service life

- Ergonomic design

- Maintenance-free

- Precision