See below for our most frequently asked questions.

Still have questions? Please contact us.

Yes. We take credit cards. We charge a 3% administrative fee.

Email to [email protected] and include quote number, shipping instructions and tax form.

If we have the press in stock at our Cranberry, PA location, then yes, we can. If it’s coming from Germany, then we can’t do anything until we have it in-house at our Cranberry, PA location. We have product flown in every week from our parent company in Germany.

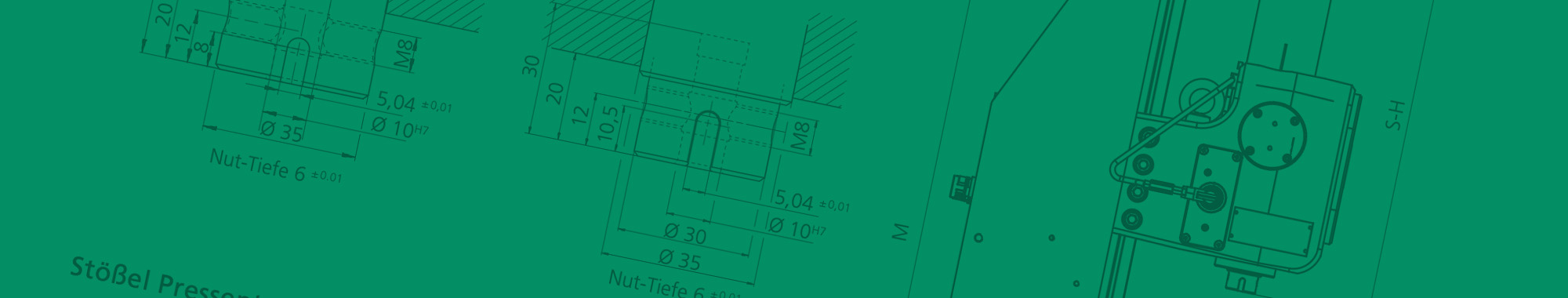

This depends on the type of press! Please refer too DWG# Press Tooling Imp, found on our downloads page, for our standard interface dimensions and tolerances.

We offer in-house tool and die design and manufacturing services and would love to assist you in developing an efficient and effective manufacturing process. This includes complimentary testing in our state-of-the-art testing lab to determine the force profile of your process. Please contact inside sales to be connected with one of our application engineers to begin this process.

Why estimate when you could know for sure? Send your parts to our Cranberry Twp., PA facility and let us precisely measure it for you! This service is complimentary to ensure you buy the right press, the first time.

If the presses are completely identical and purchased at the same time (same software revisions) it may be possible. If there is any difference between the presses it will probably not be possible. Generally, we suggest manually entering the dataset to avoid any potential problems. Please consult with our service department before trying this to determine if it is feasible.

If the presses are completely identical and purchased at the same time (same software revisions) it may be possible. If there is any difference between the presses it will probably not be possible. For servo presses it will be necessary to do a detection of the servo module before the press can be run (see next question).

Each servo press drive module has a unique serial number that must be detected before the press will run. Please consult with the service department for a procedure on how to do a drive detection.

Please consult with our service department to get an RMA number. Some simple repairs may be possible at our USA headquarters. If the problem is not repairable at our USA headquarters, then either a new or refurbished control or a complete upgrade will need to be purchased.

The PDA contains calibration info on the press. If you replace a PDA the press must be recalibrated to work accurately. Our service department can help you with this.

We understand that quality control quintessential to manufacturers, large and small. Our press controls offer a range of process tracking, from programs as simple as cycle completion, good part, bad part counts, force or stroke tolerances, to programs as complex as force profile characteristic tracking to accommodate tolerance stackup in your parts and operation. And all of this can be interfaced to your MES system with our FileXchange software. For more information, please contact inside sales.

We have a selection of standard slide (direction of travel: forward and back) and shuttle (direction of travel: left and right) tables that we offer as accessories to our press systems. Additionally, most of our press controls offer slide table functionality built in – or it can be added as a custom program by our in-house controls department. Please inquire for more information!

Absolutely! Here at Schmidt Technology Corp, we want our customers to have a one-stop shop for their manufacturing needs – we pride ourselves in our ability to work alongside customers to overcome modern day manufacturing challenges and make sure they buy what they need – nothing more, nothing less. If this means offering our services for several iterations of prototype tooling and testing to prove a process prior to press selection and purchase, we will be with you every step of the way.

The head unit is the same, just the column changes. Therefore, changes in working height. See catalog for details.