Before adjusting the stroke, be sure the head height on column is correct and ensure bolts that secure the head to column are tight.

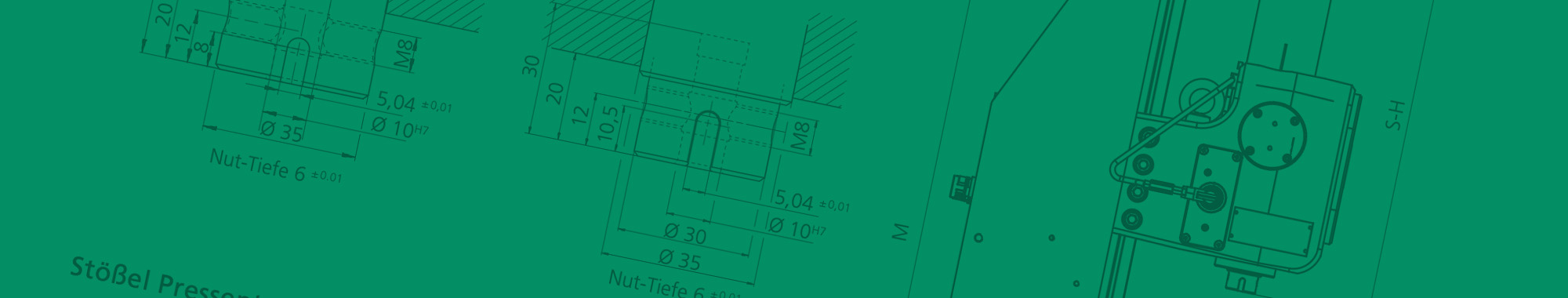

Now install the press tool and nesting fixture, then place a work piece in the fixture Adjust Work Stroke on Rack & Pinion presses as follows:

- Loosen the stroke limit block.

- Lower the ram to the desired position.

- Slide the stroke limit block down to the stop, then tighten the stroke limit block screws.

- With the standard fine adjustment; loosen the nut, turn the screw to desired position then tighten the nut.

- Model number 1 & 2 are slightly different from the shown models. The principle is the same however. SCHMIDT offers a retrofit-able micrometer as alternative to the standard fine adjustment.

- With Micrometer adjustment, loosen clamp on stroke limit block while the ram is extended, adjust the micrometer as necessary, then secure micrometer adjustment Work Stroke adjustment on Pneumatic Press.

- With PRC70, lower ram via Setup mode (Operating Manual, Page 19/20; SETUP MODE). Without PRC70, lower ram, then depressurize cylinder (ram should be extended & no pressure in cylinder)

Remove cover hood (1) - Loosen stroke limit block screws, slide block all the way down, now tighten BOTH screws Stroke fine adjustment is made via the large hex nut. The range of adjustment is approximately 6 mm / ¼”

- Turn clockwise = increase stroke

- Turn counterclockwise = decrease stroke

To change setting, loosen set screw in front. This same hex wrench is used to turn the nut Once fine adjustment is complete, adjust ram extended sensor so it is ON when Ram is within 6mm from contacting the work piece. IMPORTANT; install cover hood and secure with screw!!