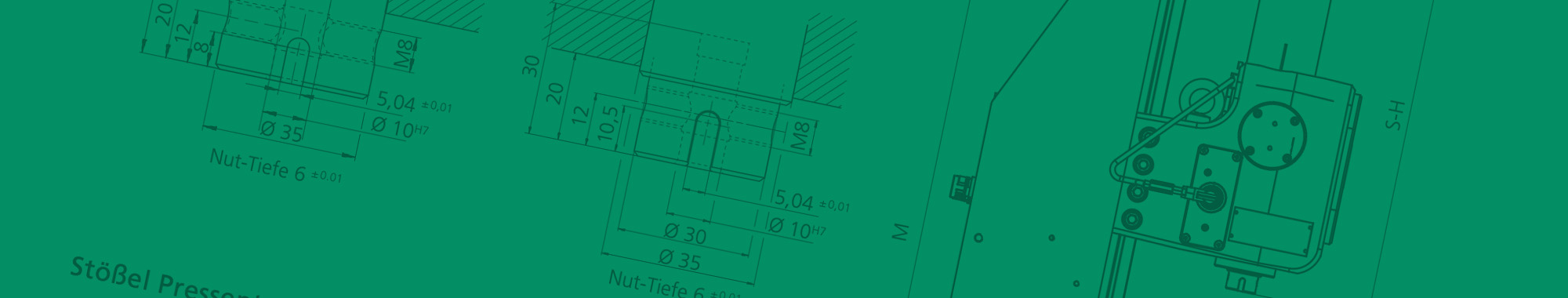

The proper function of a pneumatic Schmidt press is monitored via a variety of sensors.

It is critical for the BDC or bottom dead center sensor to be adjusted properly. Let’s take a look:

Install your fixture & upper tool in the press Place a work piece in the nest In Setup mode (w/ PRC70), extend the ram until the upper tool contacts the work piece.

Slide the sensor from bottom up. Note the point when the sensor comes ON.

From that point, slide the sensor no more than 6mm / 0.25” up.

In addition to the bdc sensor, this pressure sensor provides redundancy.

The TDC or top dead center sensor should not require adjustment. The adjustment screws are sealed.

With power / air ON and the ram retracted, the TDC or top dead center Sensor needs to be on.

The BDC and TDC sensor on the Hydro-Pneumatic are installed into the sides of the press head – BDC on left, TDC on right.