Schmidt Technology is the only company with a complete line of presses. Press capacity ranges from ounces up to 25 tons, designed for high flexibility, intelligence and productivity.

A press with integrated force and distance sensors provides 100% in-process monitoring to ensure that every part meets customer defined criteria. These presses are suitable for all environments – from heavy duty industry, to clean room, high tech and medical. In short, for anybody who produces or assembles a product.

We offer a wide range of manual presses to suit all requirements:

Manual presses for fine and precision work, low volume or at the production line.

Rack & Pinion presses lend themselves to press pins, bearings or to form, bend, join or calibrate.

Toggle presses are the choice to snap fit, coin, flare, rivet, punch, mark or cut.

The optional return lock provides quality assurance with a mechanical press.

The manual version of the 300 series presses offers enhanced process control in addition to process monitoring.

For greater productivity, use a pneumatic direct acting press, when force is required over the entire stroke. Ideal for pressing pins/bearings, forming, bending, joining, calibrating/sizing.

The pneumatic toggle press produces the force at the end of the stroke, up to approximately 6.5 tons. An ideal press for cutting, crimping, punching, flaring, marking and riveting applications.

Our hydro-pneumatic presses, also referred to as ‘air over oil’ presses, are the perfect choice when higher forces are necessary, without the mess, noise or maintenance of a hydraulic press. It is simple to operate and extremely trouble free. With an air supply of 85 psi pressure, 49,000 lbs of force can be produced at a surprisingly high cycle rate.

Like manual presses, direct acting air and hydro pneumatic presses are also available with process monitoring capability, when EVERY part needs to be inspected without adding cost and time for labor.

Finally the SCHMIDT ServoPresses, which can claim to be the most advanced and intelligent electro-mechanical presses available today. Great controllability and sophistication provides unmatched precision and flexibility that can easily help you meet demanding requirements. Real-time process monitoring is of course a standard capability of all SCHMIDT servo presses.

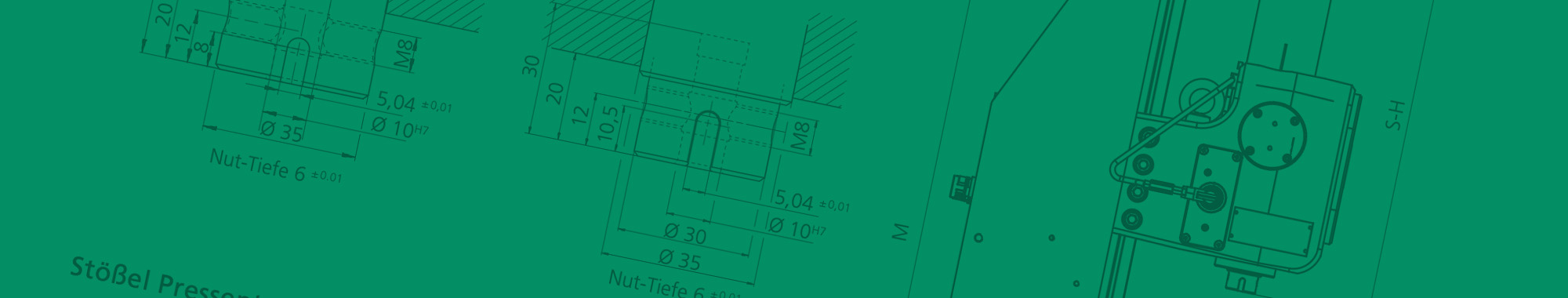

As a compliment to all presses, a great variety of accessories are offered in order to tailor a press to your exact needs.

In addition to these great presses, SCHMIDT offers engineering assistance, can customize your press and offer turnkey solutions.

Please contact SCHMIDT to discuss your pressing need.